What is cold forging?

The technology for shaping metal into desired structure by applying pressure at

room temperature. It is said to be an “Eco-friendly and efficient” processing technology because

it enables high-speed manufacturing with almost no material loss.

■Benefits of cold forging

- Less

material loss - Connects to resource-saving

- Increases

strength - Optimal to precision manufacturing

Our cold forging technology is used in various fields

-

Two Wheelers

Two Wheelers -

Four Wheelers

Four Wheelers -

OA machine parts

OA machine parts -

Other equipment parts

Other equipment parts

Aluminum cold forging. (Steps illustration)

- We select high-quality materials suited for cold forging and make precision cuts based on the set volume.

- A press is then used to form the materials into a shape which is characterized by the small clearance between the material and the die.

- This is a heat treatment process used to increase uniformity of the material structure for the cold forging process.

- Lubrication is important to reduce friction between the material and the die and prevent fusion during the cold forging process.

- Based on various experimental data and process design, forging is performed with

dimensional accuracy close to the product specifications.

>> watch the video - Depending on types on aluminum material, mechanical strength is improved by heat treatment.

- The cold forged part is then finished to the set product dimensions.

- Surface treatments such as Alumite, plating, Alodine, etc. are used to improve the external appearance of the product and increase its resistance to corrosion.

- The product then passes through a thorough inspection process before being shipped off to the customer.

群馬精工の特徴-1

Supports shortened lead time and high quality with integrated production system.

Cold forging has various merits, on the other hand forging materials at room temperature

requires more advanced technical competence.

We have accumulated forging know-how. From selection of the optimum material to design and manufacture of dies, forging and even post-processing such as machining, we have integrated production system.

Our company pursue efficient processes with prepared technologies and environment that can promptly respond to various need of customers.

We have accumulated forging know-how. From selection of the optimum material to design and manufacture of dies, forging and even post-processing such as machining, we have integrated production system.

Our company pursue efficient processes with prepared technologies and environment that can promptly respond to various need of customers.

群馬精工の特徴-2

Abundant technology and know-how for speedy die design and Production

As the lead time for product development becomes shorter the design and manufacture of dies

requires accuracy and speed.

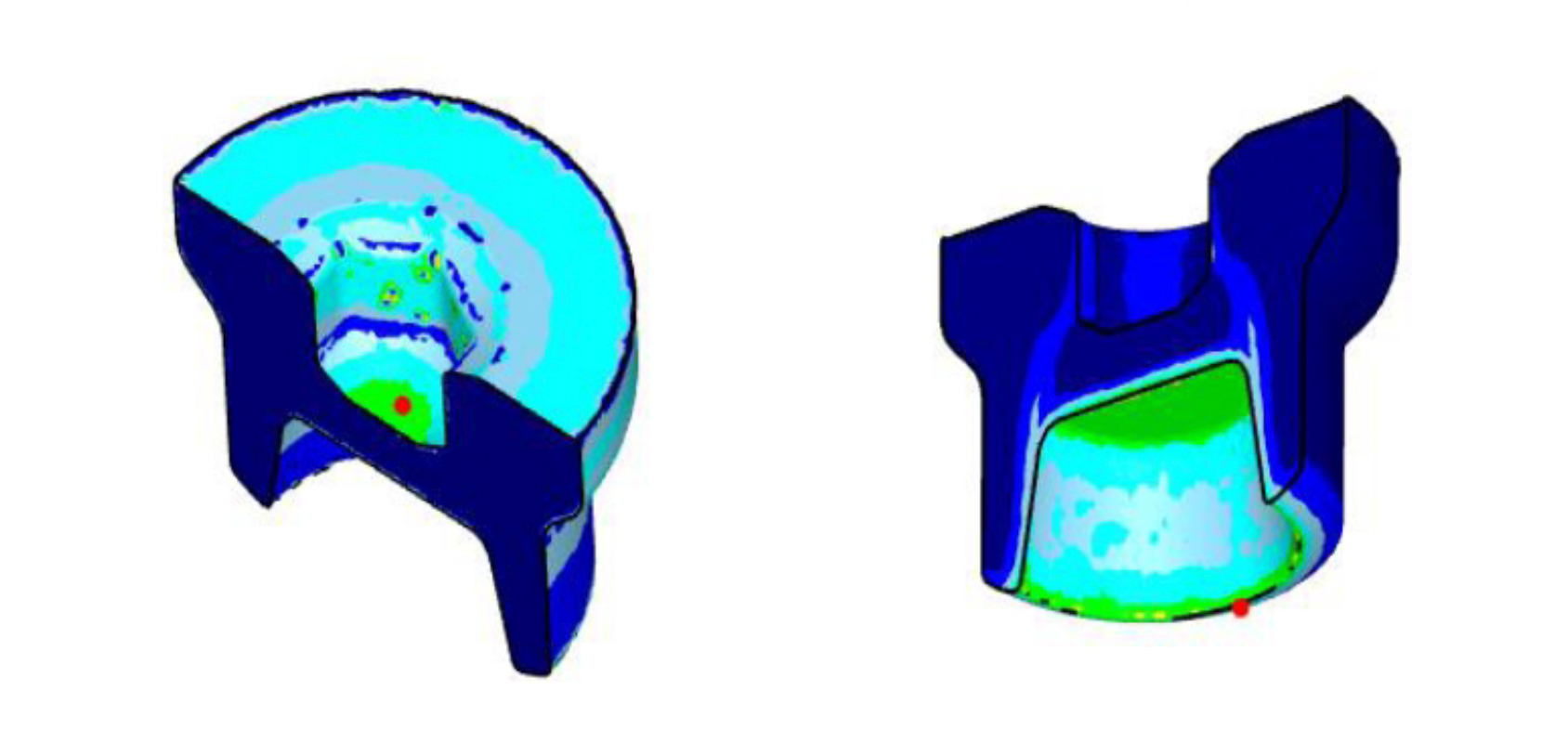

Based on our technical know-how, we have developed a system to produce dies with high accuracy and speed by researching materials for producing optimal dies. We also have a computer simulation system to digitize pressure and examine material flow during forging.

Based on our technical know-how, we have developed a system to produce dies with high accuracy and speed by researching materials for producing optimal dies. We also have a computer simulation system to digitize pressure and examine material flow during forging.

群馬精工の特徴-3

The endless pursuit for high quality

Challenge to new technology

Focusing on the forging of CFRP “Carbon fiber reinforced plastic”, a material that is expected to reduce the weight and improve the fuel efficiency of transportation equipment due to its lightweight and high strength. We are jointly researching with Kanazawa University.

Digitalization of production environment.

・Promotion of digitalization of production systemWe have introduced and operated a production control system to accurately respond to customer’s orders.

In recent years various production control system have been introduced along with the acceleration wave of digitalization.

To support the latest ordering system we have started and promoted the “Automatic ordering system ”

Technology and Sales Section

TEL. +81-274-22-7003 / FAX. +81-274-22-7590